Quality Control Process

Developed over more than four decades of our fabrication experience, our stringent Quality Control

Process serializes and subjects all operations to 100% checks and thorough recording for complete

traceability. We primarily focus on raw materials, welding joint integrity (verified by

radiography/X-rays), dimensional accuracy, and comprehensive assembly pressure testing, concluding

with ID ball Passing and Sponge Cleaning thereafter meticulous painting and packing. We consistently

exceed the requirements of leading material and fabrication codes including ASME, BSS, DIN, VGB,

JIS, NF, GOST, ISO, and EN.

Raw Material Control

Comprehensive inspection and verification of all raw materials before processing begins.

Welding Joint Integrity

Advanced radiography and X-ray verification ensures perfect welding quality.

Dimensional Accuracy

Precision measurement and quality checks for exact specifications.

Pressure Testing

Comprehensive assembly pressure testing for safety and reliability.

Complete Traceability

100% serialization and thorough recording of all operations.

Final Quality Check

Meticulous painting and packing with final quality verification.

Industry Standards Compliance

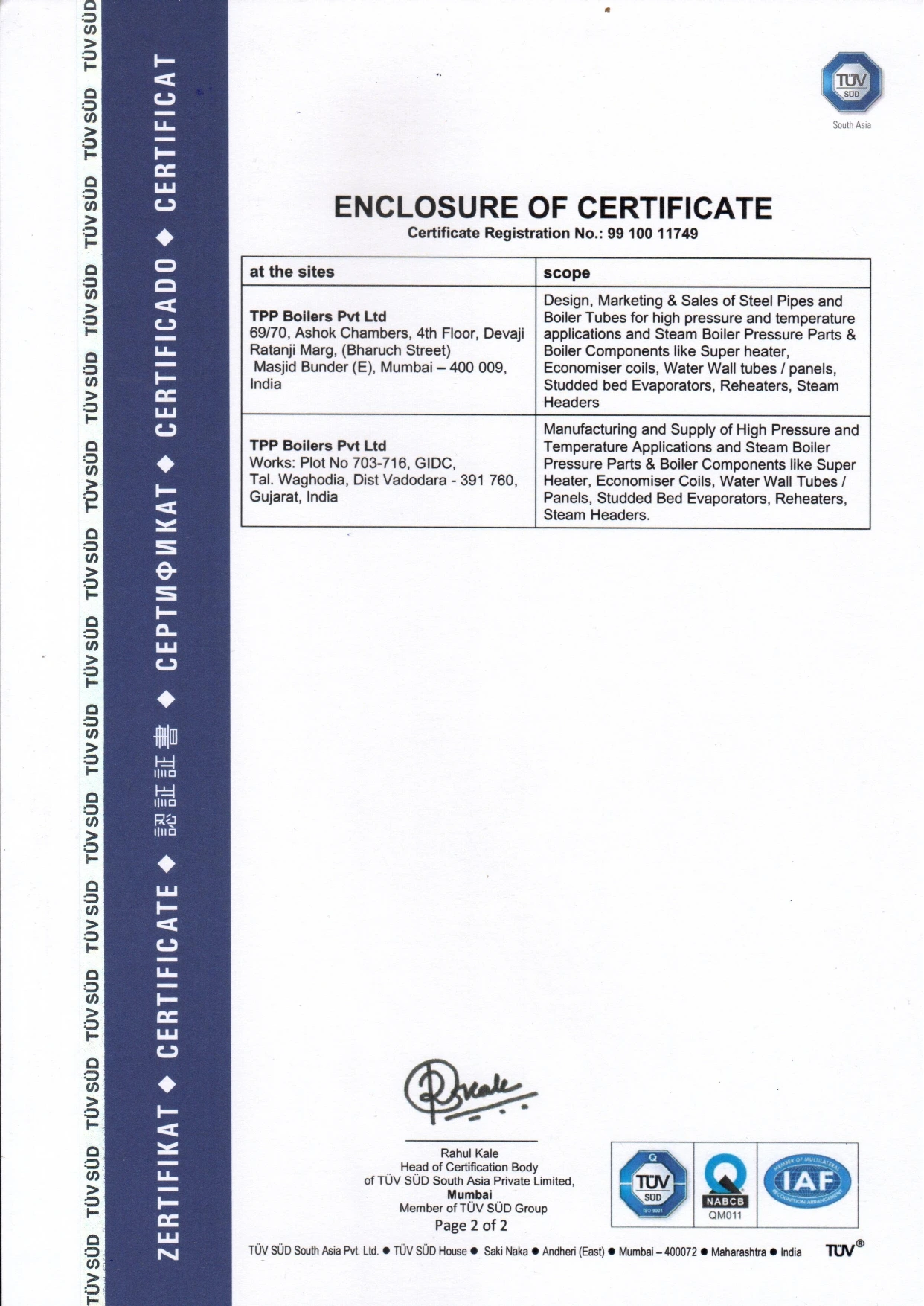

We consistently exceed the requirements of leading material and fabrication codes including:

ASME • BSS • DIN • VGB • JIS • NF • GOST • ISO • EN

_001 (002).webp)